Manufacturing is the backbone of many industries, shaping our daily products. Behind the seamless processes and high-quality outcomes lies the application of mechanical engineering principles. These principles are the foundation for design, production, and improvement in manufacturing environments. In this article, we will explore the significance of mechanical engineering in manufacturing and the core principles that drive efficiency, safety, and innovation in the field.

Design and Innovation: The Heart of Manufacturing

One key area where mechanical engineering shines is in design. Every product starts with an idea, which is then translated into a working prototype or production model. Mechanical engineers use principles like material science, kinematics, and thermodynamics to develop designs that are functional, efficient, and cost-effective.

For example, material science helps engineers select the right materials for a product based on factors like strength, durability, and weight. By understanding the behavior of materials under different conditions, mechanical engineers can prevent product failures and extend the product’s lifespan. This is particularly important in industries like automotive manufacturing, where safety and longevity are critical.

In addition to selecting materials, engineers apply principles of kinematics to design components that work in harmony with each other. This ensures that machines and systems run smoothly without unnecessary wear and tear. By designing with precision, engineers can create products that are easier to assemble, use less energy, and require fewer repairs over time.

The Role of Thermodynamics in Efficiency

Thermodynamics is another fundamental principle that plays a critical role in manufacturing. It concerns the relationship between heat, work, and energy. This principle is used to design machines and systems that are energy-efficient and environmentally friendly.

For instance, mechanical engineers apply thermodynamics to design systems that maximize energy transfer while minimizing waste in industries like power generation and refrigeration. Whether it’s improving the efficiency of a heat exchanger or developing a more effective engine, thermodynamics helps engineers optimize energy use, which leads to cost savings and a reduced environmental impact.

Manufacturers also focus on sustainable practices, and thermodynamics is crucial to developing processes that reduce energy consumption. Engineers are working on new materials and technologies that harness renewable energy sources and reduce the reliance on fossil fuels, helping the manufacturing industry meet global sustainability goals.

The Importance of Mechanics in Manufacturing Systems

Mechanics, specifically the study of forces and their effects on materials, is another critical principle in mechanical engineering. Mechanics helps engineers understand how materials respond to stresses, strains, and vibrations. This is vital when designing manufacturing equipment, such as conveyors, assembly lines, and robotic arms.

Regarding precision manufacturing, mechanics ensures that parts fit together perfectly and operate as intended. If a machine’s components are subject to excessive stress or misalignment, it can lead to malfunctions, production delays, or even safety hazards. By understanding the principles of mechanics, engineers can design more robust, accurate, and reliable systems.

One example is finite element analysis (FEA), a computational technique that allows engineers to simulate how materials will behave under different conditions. FEA helps identify weak spots in designs and optimize them for strength and durability. This ensures that manufacturing processes are efficient and that the final product meets the required standards.

Automation and Robotics: Enhancing Manufacturing Capabilities

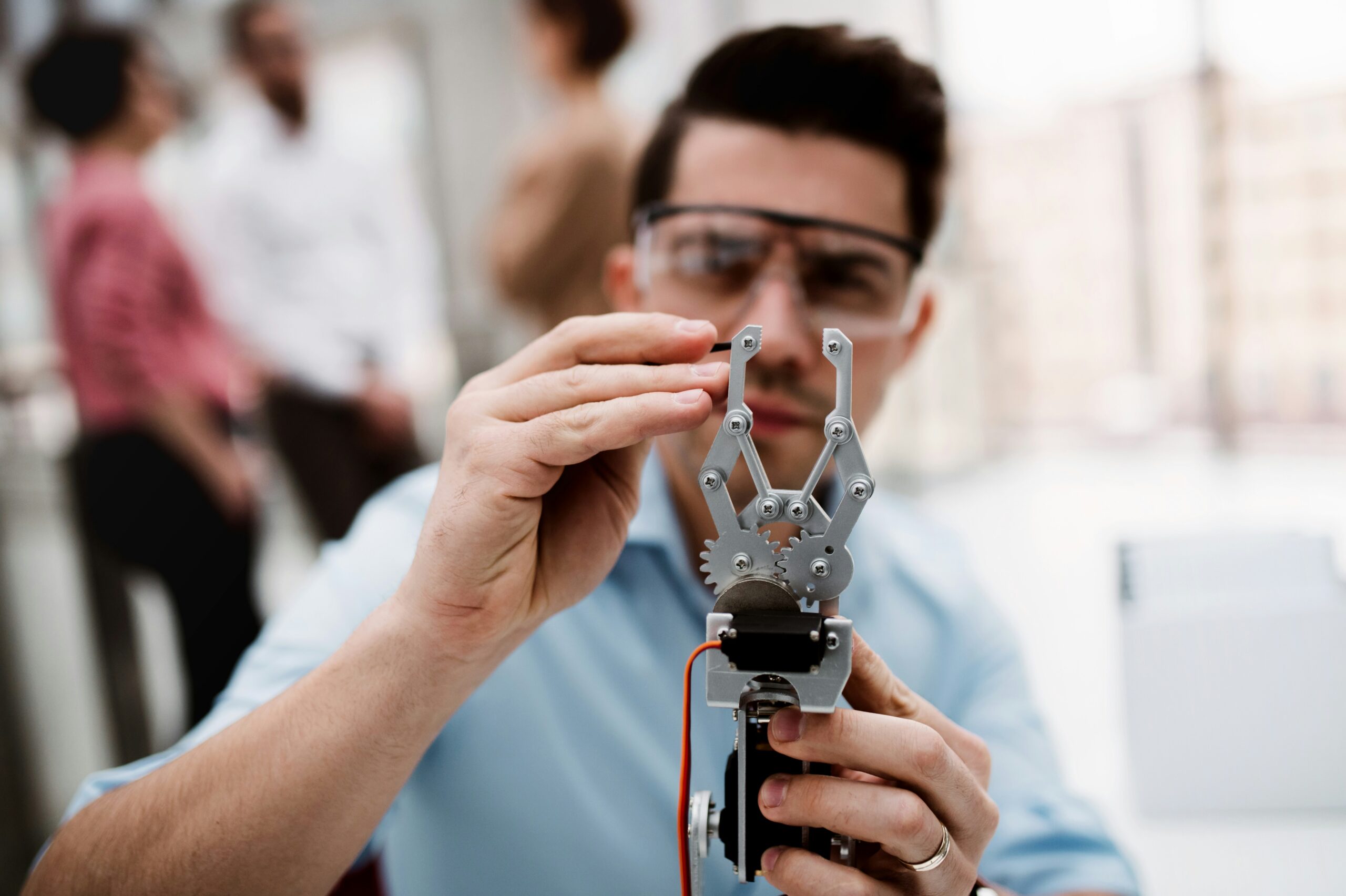

In today’s manufacturing landscape, automation, and robotics have become essential components of production lines. Mechanical engineering principles are at the core of designing and implementing these systems. Engineers can develop robotic systems that perform exact and repeatable tasks by applying concepts like control theory and dynamics.

Robotic arms, for instance, use sensors and actuators to perform complex movements, such as welding, painting, or assembling parts. Engineers apply dynamics principles to ensure that these movements are smooth and precise. This reduces the risk of errors and improves overall productivity.

Moreover, mechanical engineers use control theory to design systems that regulate the behavior of machines. Control systems ensure that robotic arms and automated machines perform tasks within the required specifications. By optimizing control systems, engineers can achieve faster cycle times, better product quality, and more flexible manufacturing processes.

Manufacturing Materials: Selection and Handling

The selection and handling of materials are crucial aspects of mechanical engineering in manufacturing. Engineers must consider the properties of materials to ensure that they can withstand the conditions they will encounter during production and throughout their lifecycle. This includes factors like tensile strength, heat resistance, corrosion resistance, and flexibility.

In addition to material selection, mechanical engineers also play a key role in handling and processing materials. They use fluid mechanics and thermodynamics principles to design systems for moving and shaping materials. For example, engineers must ensure that molten materials flow smoothly into molds and solidify properly in casting or injection molding, resulting in high-quality products.

The rise of additive manufacturing (3D printing) has introduced new challenges and opportunities in material selection. Engineers are now exploring new types of materials, such as metal alloys and composites, that can be used in additive manufacturing processes. This has opened the door to more complex and customized designs and reduced waste in production.

Maintenance and Reliability: Prolonging Equipment Life

Another key principle in mechanical engineering is maintenance. Maintaining equipment and machinery ensures that manufacturing systems run smoothly and efficiently. Engineers use reliability engineering principles to predict when parts will likely wear out and to develop preventive maintenance schedules that minimize downtime.

By applying these principles, engineers can design machines and systems that are easier to maintain and repair. This includes using standardized parts, designing equipment with fewer moving components, and creating systems that are easy to inspect and service. This results in longer equipment life and lower maintenance costs.

Reliability engineering also improves the safety of manufacturing operations. By predicting potential failures and addressing them before they happen, engineers can reduce the likelihood of accidents, ensuring that workers are safe and production continues without interruption.

Sustainability in Manufacturing: A Growing Focus

Sustainability has become a significant concern in all industries, including manufacturing. Mechanical engineering principles are at the forefront of developing environmentally friendly practices that reduce waste, energy consumption, and pollution.

Engineers are working on designing products that are easier to recycle, using renewable energy sources for manufacturing processes, and minimizing the environmental impact of operations. This is particularly important in industries like automotive manufacturing, where the demand for electric vehicles and energy-efficient designs is rapidly growing.

In addition, the integration of life cycle analysis (LCA) into product design is helping engineers assess the environmental impact of manufacturing processes from start to finish. Engineers can design more sustainable systems that align with global environmental goals by considering factors like resource usage, waste production, and energy consumption.

The Unseen Drivers of Modern Manufacturing

Mechanical engineering principles are the unseen drivers behind modern manufacturing. From design and innovation to automation, materials handling, and sustainability, mechanical engineers are essential in shaping the future of manufacturing. By applying these principles, engineers ensure that products are made with precision, efficiency, and reliability, meeting the needs of consumers and businesses alike.

As technology evolves, mechanical engineers will be more critical in advancing manufacturing capabilities. By harnessing the power of innovation and applying fundamental engineering principles, they will continue to push the boundaries of what is possible in the manufacturing world.