Mechanical engineering is a broad and foundational field in engineering. It shapes the way machines work and how we solve real-world problems. To succeed in this discipline, every engineer must understand key principles that guide design, analysis, and innovation. These principles provide a framework to approach complex tasks with confidence and accuracy.

Understanding these core concepts strengthens an engineer’s ability to create efficient and reliable solutions. Whether working on small components or large systems, these ideas remain essential. Let’s explore these fundamental principles and see why they matter.

The Importance of Mechanics and Motion

The study of mechanics lies at the heart of core mechanical engineering. Mechanics explains how forces act on objects and how those objects move or stay still. Engineers use this knowledge to predict and control movement, which is vital when designing parts like gears, engines, or robotic arms.

Newton’s laws of motion form the backbone of this area. They describe how an object reacts when forces apply to it. For instance, an object at rest stays at rest until acted upon by a force. This concept helps engineers ensure safety and performance by calculating forces on structures and machines.

The motion also involves energy. Engineers study kinetic energy—the energy of moving objects—and potential energy—the stored energy based on position. Understanding energy transfer allows engineers to design systems that use power efficiently. For example, converting chemical energy into mechanical energy in engines depends on this principle.

Thermodynamics: Managing Heat and Energy

Another core principle is thermodynamics, which deals with heat, work, and energy transfer. This field explains how energy moves and changes form. Engineers apply thermodynamics to improve machines like engines, refrigerators, and power plants.

Thermodynamics revolves around key laws that govern energy flow. The first law states that energy cannot be created or destroyed but can change forms. Engineers must account for energy input and output to optimize system efficiency.

The second law highlights energy’s tendency to disperse, reducing usable energy over time. This concept is crucial for understanding why machines cannot be 100% efficient. Engineers use this insight to design systems that minimize energy loss and waste.

Engineers develop better cooling systems, more efficient engines, and innovative energy solutions by mastering thermodynamics. These applications are critical in industries ranging from automotive to aerospace.

Materials Science: Knowing What Things Are Made Of

Core mechanical engineering requires a deep understanding of materials and their behavior. Materials science studies how substances react to forces, temperature, and environmental conditions. This knowledge is vital to choosing the right material for a task.

Different materials have unique properties, such as strength, ductility, hardness, and fatigue resistance. Selecting a material that can withstand stress without breaking or deforming is essential. For example, the steel used in bridges must support heavy loads and resist corrosion.

Engineers also consider manufacturing methods and costs when choosing materials. Some materials are easy to shape but expensive, while others may be cheaper but less durable. Balancing these factors affects a product’s success and lifespan.

Materials science also helps engineers understand failure modes. Knowing why and how materials fail guides design improvements and safety standards. This reduces accidents and increases reliability.

Fluid Mechanics: Understanding Liquids and Gases

Fluid mechanics studies the behavior of liquids and gases in motion or at rest. This principle is significant in systems like pumps, turbines, and ventilation. Understanding fluid flow helps engineers design equipment that efficiently moves air, water, or fuel.

Fluids behave differently from solids because they can flow and change shape. Engineers use equations to predict pressure, velocity, and flow patterns. Fluid mechanics explains lift and drag forces in airplane wings.

This principle also aids in controlling heat transfer through fluids. Cooling systems in engines and electronics rely on fluid movement to carry away excess heat.

Without fluid mechanics, engineers could not develop many modern technologies that depend on fluid flow. This includes everything from water supply systems to aerospace propulsion.

Control Systems: Directing Mechanical Processes

Core mechanical engineering often includes control mechanisms that manage operations automatically. Control systems use feedback loops to maintain desired performance. For example, cruise control in cars adjusts speed based on road conditions.

Engineers design control systems to regulate temperature, pressure, and position. These systems improve precision and safety in machines and processes.

Understanding how to model and analyze control systems helps engineers predict how a system will respond to changes. This reduces errors and improves reliability.

Control principles also intersect with electronics and computer engineering. Mechanical engineers who grasp control theory can work on advanced robotics and automation projects.

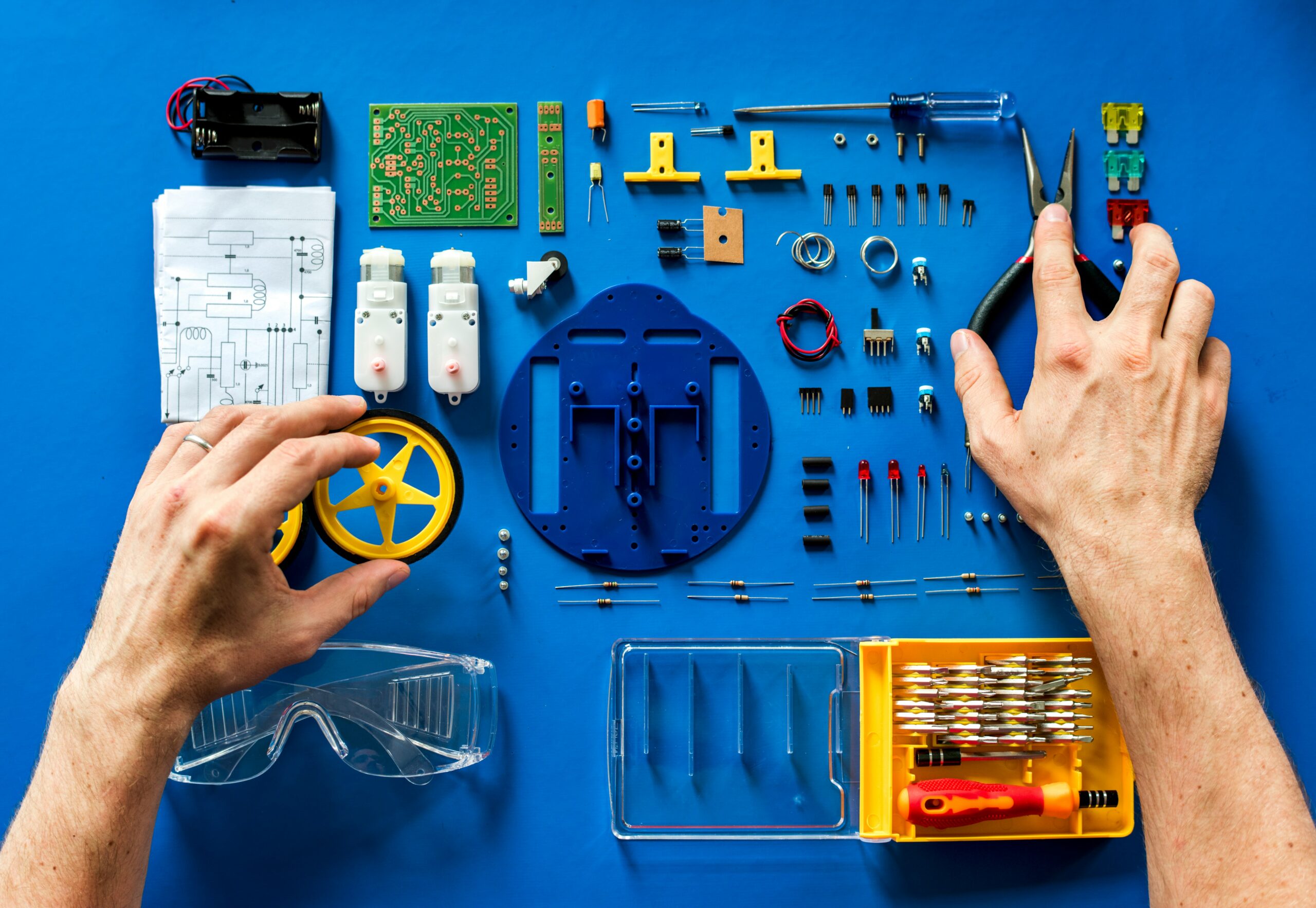

The Role of Design and Manufacturing

Mechanical engineering goes beyond theory. Applying principles to create real products is essential. The design transforms ideas into practical, manufacturable solutions.

Good design balances functionality, cost, and manufacturability. Engineers use computer-aided design (CAD) tools to visualize and test components before production, reducing errors and development time.

Manufacturing principles focus on processes like machining, casting, and welding. Knowing these methods allows engineers to design parts that are easier and cheaper to make.

Design and manufacturing also emphasize tolerances and quality control. Precise specifications ensure parts fit and work together as intended, which is critical in industries like aerospace and automotive, where safety matters most.

Problem-Solving and Analytical Thinking

At its core, mechanical engineering demands strong problem-solving skills. Engineers face complex challenges that require creative and logical thinking. They analyze data, apply principles, and test solutions repeatedly.

Breaking down significant problems into smaller, manageable parts helps. Engineers use modeling and simulation to explore different scenarios. This approach reduces risk and improves designs.

Additionally, communication is key. Engineers must explain their findings clearly to teams and clients. Collaboration often leads to better outcomes by combining different perspectives.

Developing a systematic approach to problem-solving enhances efficiency. It also builds confidence in handling unfamiliar situations or technologies.

Continuous Learning and Adaptation

Mechanical engineering is a constantly evolving field. New materials, technologies, and methods emerge regularly. Successful engineers commit to lifelong learning.

Staying updated on trends and innovations allows engineers to apply the latest tools and techniques, keeping projects competitive and efficient.

Adapting to change also means embracing new challenges with flexibility. Engineers who can learn quickly and apply knowledge across disciplines excel in their careers.

Core mechanical engineering principles provide the foundation for all engineering work. Mechanics, thermodynamics, materials science, fluid mechanics, control systems, and design all intertwine to create effective solutions. Strong problem-solving skills and a commitment to continuous learning complete the picture.

Mastering these principles equips engineers to innovate and improve the world around them. It empowers them to build machines, structures, and systems that work safely and efficiently. With these fundamentals, every engineer can face challenges confidently and make a lasting impact.